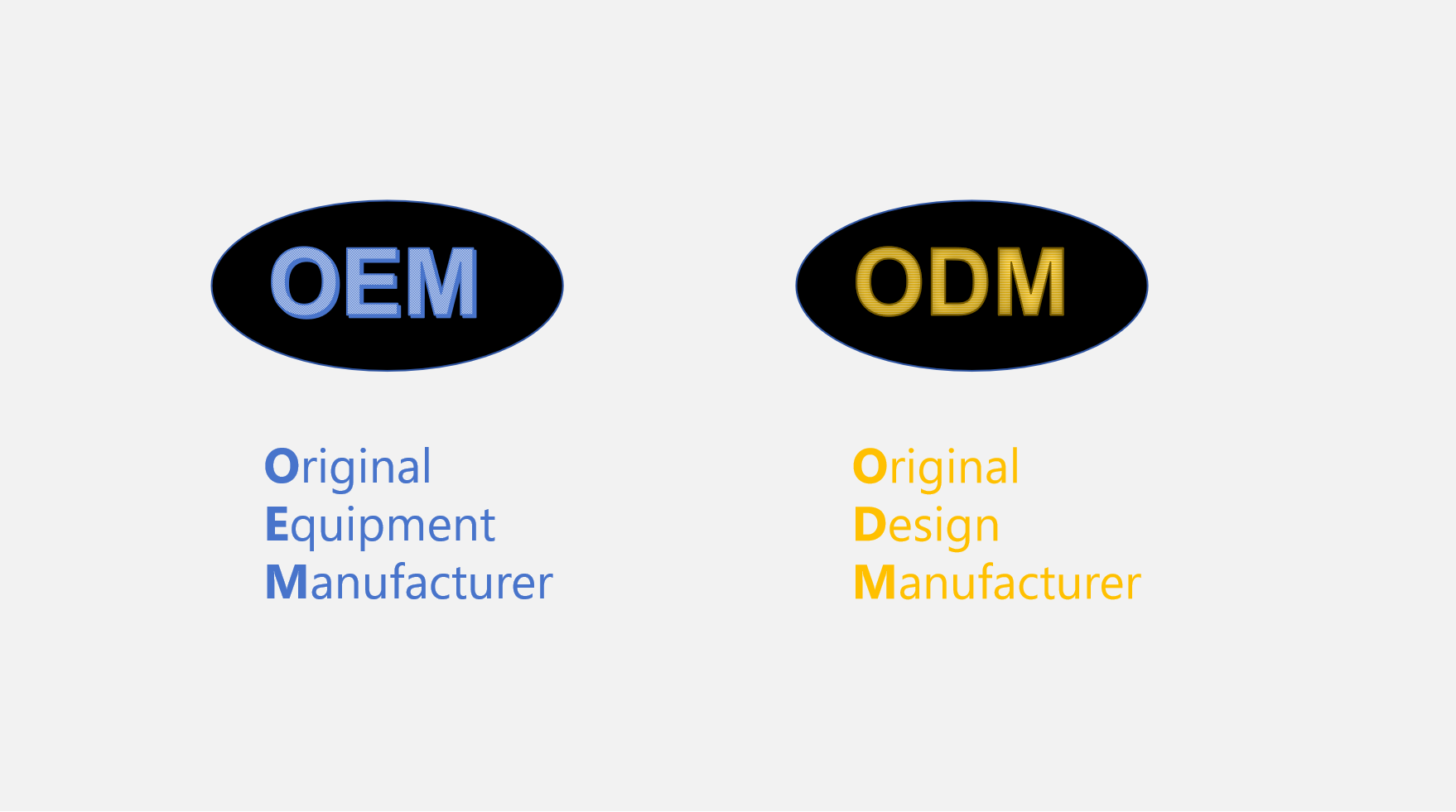

Over the past few decades, China has become a global leader in OEM/ODM manufacturing, playing a pivotal role in the supply chains of countless industries. Whether you're a startup launching a new product or a well-established brand seeking to expand your catalog, understanding the OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) models is essential to navigating China's vast manufacturing ecosystem effectively. In this blog, we explore the key advantages, considerations, and best practices for working with OEM/ODM manufacturers in China.

OEM refers to manufacturing based on a buyer's design and specifications. The factory produces products under the buyer's brand, usually without contributing to the product's development.

ODM, on the other hand, involves manufacturers that not only produce goods but also design them. Businesses can choose from pre-developed products and customize aspects such as packaging, color, or branding.

| Feature | OEM | ODM |

| Product Design | Provided by the buyer | Developed by the manufacturer |

| Intellectual Property | Retained by the buyer | Often retained by the manufacturer |

| Customization | High (from the ground up) | Moderate (based on existing models) |

| Development Cost | Higher | Lower |

Understanding these differences helps you decide which model suits your business goals, budget, and timeline.

China's reputation in OEM/ODM manufacturing is not accidental. A combination of robust infrastructure, skilled labor, cost efficiency, and specialization has positioned the country as a top choice for global businesses.

From electronics and textiles to toys and household goods, China offers access to a broad range of specialized manufacturers. This makes it easier for businesses to find partners who understand the nuances of their specific product category.

Whether you're looking to produce a few thousand units or scale to mass production, Chinese manufacturers are equipped to handle varying volumes with consistency.

In regions like Guangdong, Zhejiang, and Jiangsu, suppliers, component makers, and logistics providers are clustered in close proximity, leading to reduced lead times and streamlined operations.

While labor costs in China have risen in recent years, the total cost of manufacturing—including materials, tooling, and logistics—remains highly competitive, especially for medium to large volumes.

Startups & Small Brands: ODM services allow quicker market entry with lower upfront costs.

Established Brands: OEM services provide greater control over product specifications and branding.

Retailers & Distributors: OEM/ODM products help expand private label offerings efficiently.

E-commerce Sellers: Platforms like Amazon and Shopify thrive on unique, well-branded products that OEM/ODM services can help create.

While OEM/ODM manufacturing in China offers many benefits, businesses should be prepared to address several challenges:

Ensuring product quality requires clear communication, sampling, and consistent inspection processes. Factory audits and third-party inspections are highly recommended.

If your design or brand is unique, it's crucial to register trademarks and patents in China and use legally binding NDAs (non-disclosure agreements) before sharing proprietary information.

Most OEM/ODM factories have minimum order requirements, which may be a barrier for smaller orders. However, negotiation is often possible, especially if you work with experienced sourcing agents.

Misunderstandings can occur without proper translation and cultural context. Having on-the-ground support or sourcing partners can help bridge this gap.

Look for manufacturers with industry certifications, verified export experience, and client references. Platforms like Alibaba or Canton Fair visits can be starting points, but vetting is essential.

Detailed specifications, drawings, and quality standards reduce errors. Include tolerances, materials, packaging, and testing requirements.

Samples help you check functionality, aesthetics, and quality before making a large investment.

Define payment terms, lead times, quality expectations, and after-sales obligations in writing. Preferably, use bilingual contracts enforceable under Chinese law.

Working with a reliable sourcing company like YiwugoMU helps ensure that communication is smooth, expectations are met, and your interests are protected at every step—from factory selection to shipment.

A reputable sourcing company does more than just match you with a factory. Here's how they add value:

Local Knowledge: Understanding regional specialties and identifying the right suppliers.

Quality Control: Organizing inspections and ensuring standards are met.

Negotiation: Bridging cultural and business negotiation styles.

Project Management: Tracking timelines, handling changes, and mitigating risks.

Consolidated Shipping: Helping combine products from multiple factories to save on logistics.

At YiwugoMU, we collaborate with a broad network of vetted manufacturers and bring hands-on experience to help clients succeed with their OEM/ODM projects in China—efficiently and confidently.

The world of OEM/ODM manufacturing in China continues to evolve, offering unmatched opportunities for product innovation, cost-effective production, and business growth. While challenges exist, they can be successfully navigated with careful planning, the right partnerships, and clear communication.

For businesses looking to bring new products to market or optimize existing supply chains, China's OEM/ODM capabilities are hard to overlook. And having a trusted sourcing partner by your side—one that understands both Western expectations and the nuances of Chinese manufacturing—can make all the difference.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent